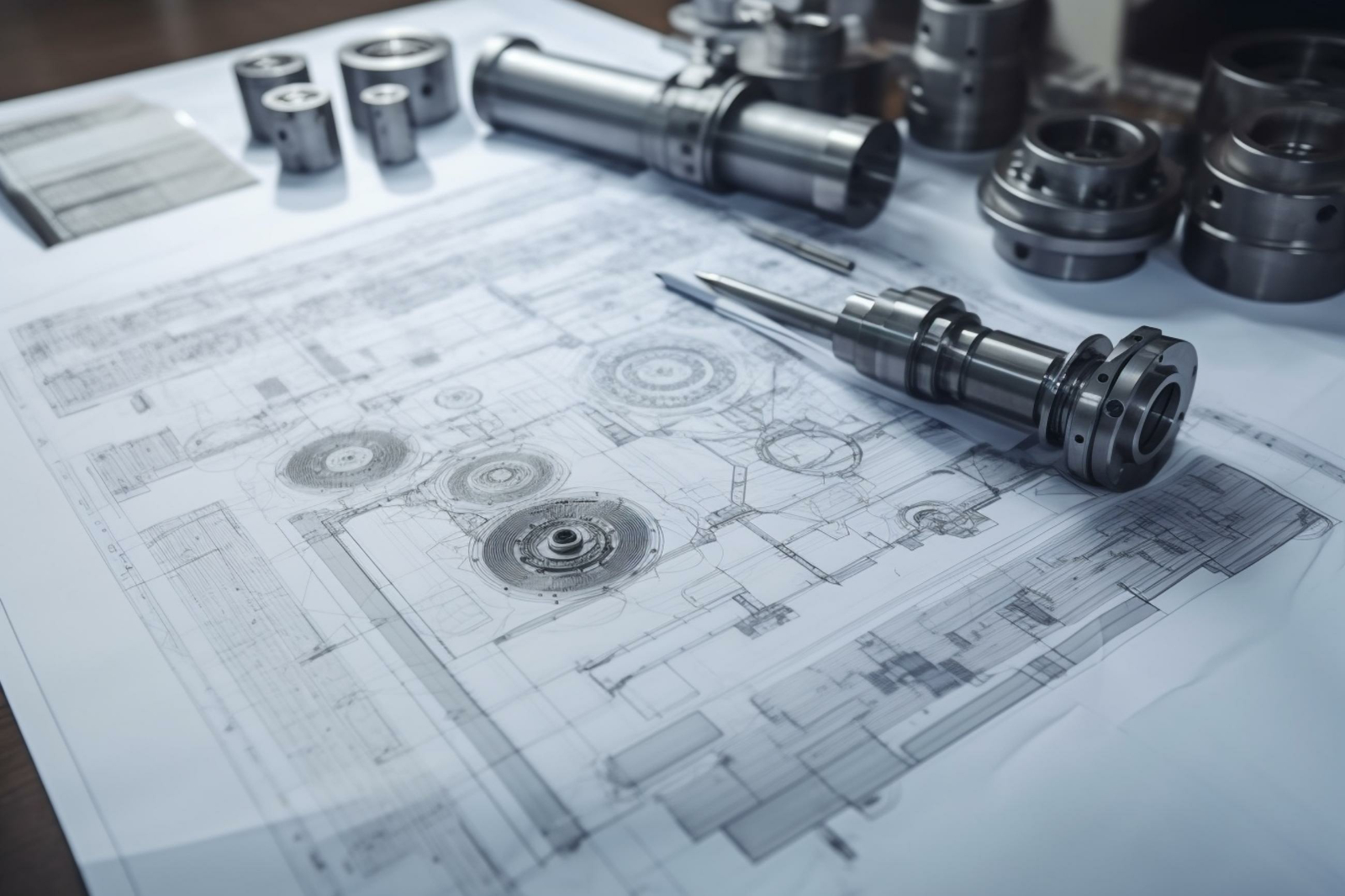

Machine reconditioning involves the restoration and refurbishment of used machines, turning them, once again, into efficient and high performance equipments, thus enabling the residual value of aged machines to be taken advantage of and service life extended. The general steps in the machine reconditioning process are:

Initial assessment

We evaluate the condition of the used machine to determine its overall condition and identify any components or systems needing repair work or replacement. This initial evaluation includes all parts of the machine, generator, electrical system, controls, structure, and more.

Disassembly

After inital assessment and estimative of costs, upon customer’s request, we disassemble the machine to access and examine each component individually. This will allow us to perform a more detailed inspection and identify any damage, wear, or failure.

Cleaning and waste removal

We remove oil and other residues accumulated on the machine over time. We clean thoroughly and carefully each part, using appropriate methods and products, in order to prepare the machine for the next step.

Repairs and exchanges

Based on the initial assessment, we carry out the necessary repairs on each of the damaged or worn components. This may involve replacing parts, grinding worn surfaces, repairing electrical wires or cables, among other interventions.

Updates and improvements

There is the possibility to perform/recommend upgrades or make improvements to the machine during the rebuild process. This may include replacing older components with newer versions, updating control systems, implementing more efficient technologies, and other improvements.

Testing and adjustment

After finishing repairs and upgrades, we carry out the necessary tests and trials to guarantee its good functioning and attest it with PORTBRIDGE certification seal.

Assembly

After testing and PORTBRIDGE certification, we proceed with the final assembly of the machine. We guarantee the correct installation and adjustment of the components according to the technical specifications.

Painting and finishing

if needed and upon customer's request, we can repaint the machine to improve its appearance/aesthetics and protect it from corrosion. We also perform finishing works, such as proper lubrication of all moving parts.

Documentation and certification

We record every step of the reconditioning process, including all details of the repair performed, the potential upgrades implemented, and the test results. This documentation will be useful for future reference and to certify the quality of the work performed.

Warranty and after-sales support

If the reconditioned machine is sold to a third party, we offer warranty and after-sales support.